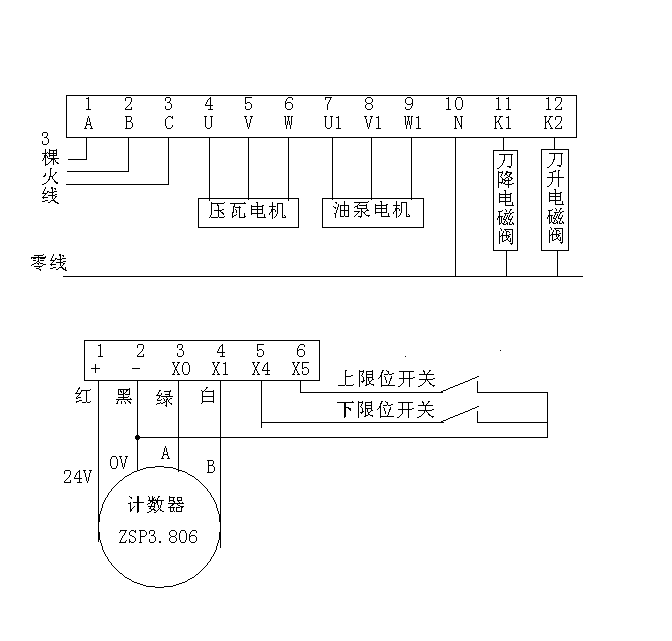

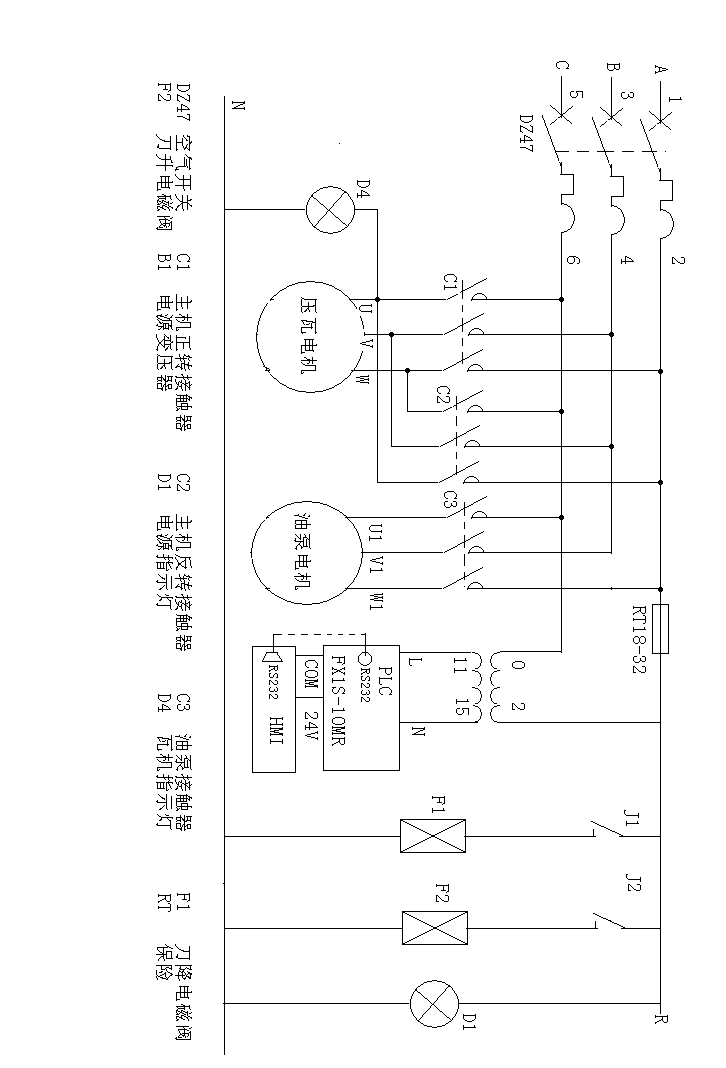

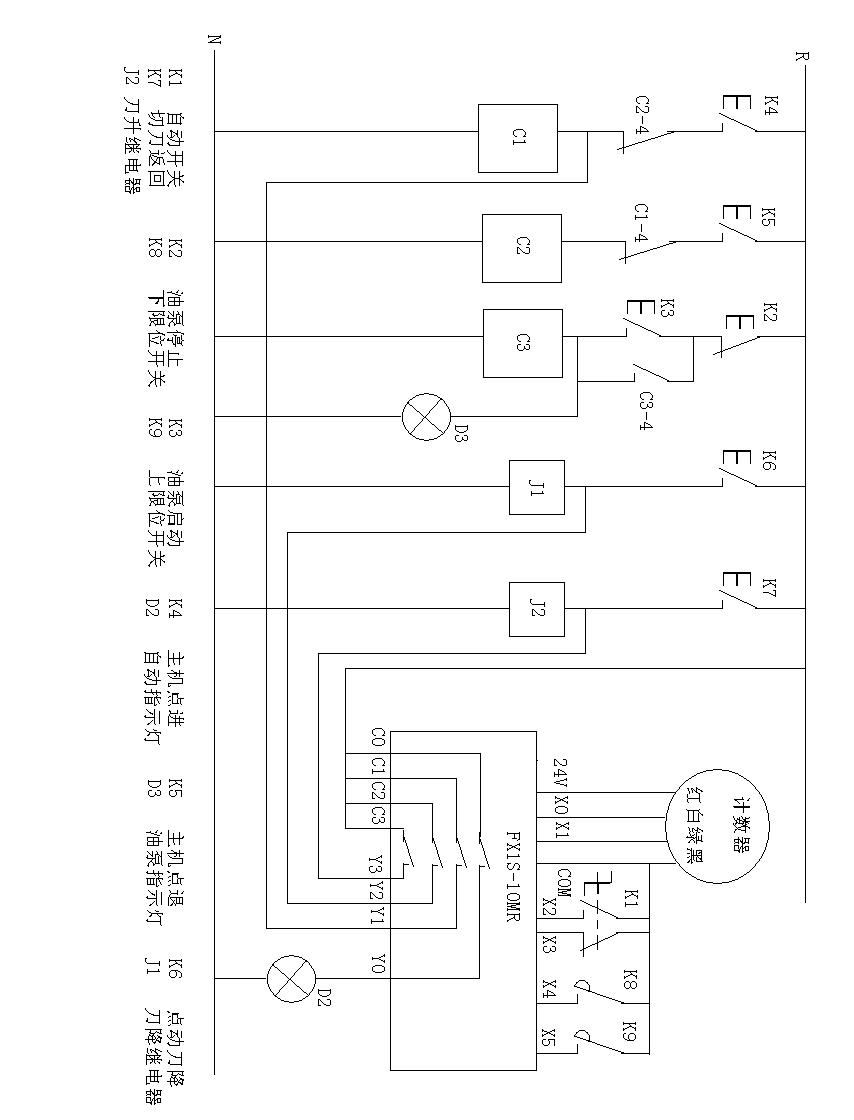

机器电源为3火1零,3棵火线分别接接线排A、B、C(1、2、3),零线接N(10)并且接电磁阀公用零线,U、V、W(4、5、6)接压瓦机电机,U1、V1、W1(7、8、9)接油泵电机,落刀电磁阀控制线接K1(11),升刀电磁阀控制线接K2(12)。

Machine electrical source is three live wire and one zero line.Three live wires are respectively connected with row A,B,C ,and zero line with N besides electromagnetism clique public zero line , U,V,W connected with electrical engine of roll forming machine ,U1,V1,W1 with oil pump electrical engine,droping reamer electromagnetism clique control line with K1(11),and ascending reamer electromagnetism clique control line with K2(12).

按键说明:

- SET键修改选择键;ENT键确认键。ESC 已工作长度清零键,ALM 已工作张数清零键,∧,∨画面转换键。CLR 改数时清零键。0——9 数字直选键。

SET is amending and selecting key ;ENT is affirming key ;ESC is the key to clear work longth ;ALM is the key to clear woor sheet numbers; ∧,∨ is menu transition key ;CLR is the key to clear altered numbers.0—9 is keeping choosing key.

简单操作:

Simple operation

送电前应把自动开关拧到关位置(逆时针拧一下)!!。

Recloser is wrested to close position Before sending electricity (negative hour hand )

- 按下油泵启动钮。注意油泵电机转向。

- Press oil pump start-up button. Notice turnaround of oil pump electrical engine .

- 按住瓦机前进,将板走到刀口外,按住剪刀降切断板,按剪刀升将刀升到上限位。

- Press tile machine and go ahead ,make the plate go to the outer of knife-edge,press scissors and decline to cut off board,press scissors and ascend the reamer to upper limit location.

- 显示工作画面状态下,按ALM键清零当前张数;按ESC键清零当前长度。

- When showing work menu predicament ,press the key of ALM to clear current sheet numbers;press ESC key to clear current length.

- 显示工作画面状态下,按SET键选择长度或张数。(按一次SET键,张数数值被黑框框住,再按一次,长度数值被框住,每按一次SET,张数和长度交替被框住一次,数值只有被框住变成黑色时才可以改变)。按CLR键清零。按数字键输入。(由高位向个位。例:12张;输入1,2。3米4输入3、4、0、0MM)。

- When showing work menu predicament ,press SET key and choose length or sheet numbers.(press once SET key,and count of sheet number is circled by black frame.Press again, length numerical value is circled;Press SET key at a time,sheet number and length is circled by turns, numerical value is changed when it is circled to turn into black ).Press CLR to clear.

- 按ENT键确认。(数值改完必须按ENT键,否则无效)

- Press ENT to make sure(Press ENT after changing numerical value,or else it is of no effect. )

- 全部设完后拧开自动开关(顺时针拧一下),机器按设定数据开始工作。工作完成后机器自动停止。如果相同长度还需要继续工作,只要按一下ALM键(已切张数清零键),机器就会按照显示屏上设定的数再工作一遍。如果需要变换长度应把自动开关拧回。然后再设定下一个生产任务。并且注意下次启动自动前清零已切张数(按一下显示屏上ALM键)。

- After seting up,wrest recloser(wrest in agreeable hour hand ),the machine work according to enacting data,and stop automatically after the work is completed.If it need continue to work with same length,press ALM key(the key to clear woor sheet numbers),the machine will work again according to enacting data of show screen.If it need to chang length , wrest the automatic recloser back.And then enact next production task.And notice before starting up auto next time to clear already cutted sheet numbers(press ALM key in show screen).

- 中途停机只需把自动开关拧回(逆时针拧一下),继续工作时再拧开自动开关即可。

- Wrest automatic recloser if it need to stop machine in midway(negative hour hand);if it continue to work ,you open automatic recloser.

- 如果板的长度和要求不相符,按 ∧ 键或∨ 键至调整画面,在原补偿量基础上重新调整补偿量加或补偿量减。(校正前板长度+补偿量加-补偿量减=校正后板长度)

- If the length of plate does not agree with request,press ∧key or ∨key to adjust menu,and readjust compensate quantity adding or compensate quantity reducing in the base of original compensate quantity.(emending front board length+ compensate quantity adding - compensate quantity reducing=board length after emending)

- 减速距离为变频机用,一般为200毫米,普通机此数值无意义。

- Decelerating distance is used by frequency conversion engine and commonly is 200mm,and general engine is inanition for the numerical value.

Break down exclusion

手动能工作,自动不能工作:

Manus can work ,but self-motion can’t work;

1 已切张数大于或等于设定张数。处理方法:清零当前张数(按一下ALM键)。

Already cutted sheet nmuber is big in or equal to enacting sheet nmuber.Handling method:to clear current sheet number(press ALM key)

2张数或者长度没有设数。

Sheet number or length is not enacted.

3自动开关钮损坏。(可用任意牌子LAY3系列旋钮代替)

Recloser button is damaged.(It can be replaced by LAY3 series knob in random brand)

手动自动都不工作,显示屏没有显示:

Manus and self-motion can’t work ,and show screen can’t display.

1电源不正常

Electrical source is abnormal.

2保险丝熔断。处理方法:更换并检查电磁阀线有没有损坏。(保险丝型号6A)

Fuse is melt and break. Handling method:repalce and examine if electromagnetism valve is damaged.(fuse model is 6A)

手动自动都不工作,电压表显示200V以下,显示屏有显示:

Manus and self-motion can’t work ,and pressure table display less than 200V,and shouw screen have show.

1零线断路。检查电脑外部零线。

Zero line is turnoff. Examine zero line of outer of computer.

只要拧开自动切刀一直向上走:

If only wrest automatic cutting reamer and go upwards at all times.

1 上限位开关断路性损坏。

Upper limit location switch is turnoff and damaged .

2电磁阀卡住。处理方法:关掉油泵,用改锥从电磁阀两端来回捅电磁罚的手动复位销。先从浅的一端往里捅,然后从两端来回捅,一直到用手捅下

时感觉有弹性时止。

Electromaganetism val Electromaganetism valve ve is locked . Handling method: turn off oil pump,use screwdriver to disclose manus replacement pin of electromaganetism valve in come-and-go .First disclose from the low end, then disclose from two ends in come-and go,until you disclose and feel elasticity by hand .

只要一开油泵,切刀一直向下:

If only open oil pump,cutting reamer goes upward at all times.

电磁阀卡住。处理方法:关掉油泵,用改锥从电磁阀两端来回捅电磁罚的手动复位销。直到感觉到有弹性时止。

如果电磁阀经常卡住,应换油并清洗电磁阀。

Electromaganetism valve is locked.Handling method: close oil pump , Electromaganetism valve,until you feel elasticity.

If electromaganetism valve is often locked ,you need chang oil and clean out Electromaganetism valve .

注意事项:

Noticng proceeding:

1设备带电作业时注意安全。设备接安全地线。

2任何时候不能把手或者异物伸入刀口。

3电器柜注意防雨防晒;计数器防止硬物撞击;线防止被板撞断。

4机械配合活动部位经常加润滑油。

1 Give your attention to safety when the facility is busywork with electrification.The facility is connected with safe ground line.

2 At any time don’t put your hands or eyewinker to knife-edge.

3 electric facility is prevented from rain and sun shine;counter is avoid to strike by forcible matters;line is prevented from bump and break by plate.

4 machine cooperation movement part often add lube.

HEBEI FEIXIANG ROLL FORMING MACHINERY CO.,LTD

Address:Yingbin Road Industrial development botou city

Tel/whatsapp/wechat/QQ:008613582472696

全 自 动 压 瓦 成 型 机

Auto sheets roll forming machine

使用说明书

Specification

河 北 飞 翔 压 瓦 机 械 制 造 有 限 公 司

Hebei feixiang roll forming machinery Co.,Ltd