Product Description

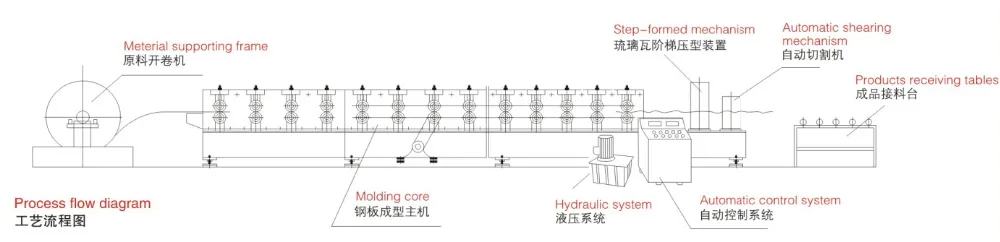

Flow chart:

Main technology:

Technique parameters of the processing line

(1) Coil material: EPS, rock wool, glass silk floss and so on

(2) Thickness of the plate: 0.3-0.8mm

(3) Core thickness: 20-300mm

(4) Production capacity (according to your glue):

4-4.5m/min (the fastest), 2-2.5m/min(the slowest)

(5) Total power: about 30KW

(6) Weight: 25ton

(7) PLC control systerm, easy to operate, high precision and work stably.

(8) Dimensions of whole production line:

About Length35000mm × Width2500mm × Height2600mm

ptional Choice

|

1. |

Electric Uncoiler/Hydraulic Uncoiler |

|

2. |

Robstic Structure |

|

3. |

Automatic Stacker |

|

4. |

Logo Punching Machine |

|

5. |

Safety Cover |

Pictures Show

Colorful stone coated metal roof tile is a modern environmentally friendly roofing material with the basic of 0.4mm Al-zine coated steel.

Covering color vermiculite surface which carried under the high temperature technology.

It is high-performance, stable, energy-efficient and easy operation.

Sample roof panel:

|

NO. 1 Auto bottom glue spraying section |

|

|

Appearance size |

4000*1000*2000mm |

|

Driving section |

3KW Excitation motor or frequency speed regulation (AS per customers’ requirements ) |

|

Automatic pressure spray tank |

1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

|

Automatic glue machine motor |

Servo motor ; Power: 750w ; PLC |

|

Automatic spray gun |

4 set (spare parts) |

|

Dust collecting fan |

1 set ; Power: 200w |

|

Damp proof lamp |

1 pc ; Power: 100w |

|

Conveying device |

Chain reciprocating |

|

Air compressor |

1 set ; Power: 7.5kw |

|

Dust control of axial flow fan |

1 set ; Power: 200w |

|

Agitator |

1 set ; Power: 1.5kw |

|

NO. 2 Auto stone coated section |

|

|

Appearance size |

3500*1000*1500mm |

|

Framework |

Steel welding |

|

Conveying device |

Chain reciprocating |

|

Automatic sand hopper |

1 set ; Capability: 200kg |

|

Bucket lift |

1 set |

|

Manual sandblast gun |

4 sets |

|

NO. 3 The first time drying section |

|

|

Appearance size |

25000*1000*1200mm |

|

Framework |

Steel welding |

|

Frame type thermal insulation wall |

1.2mm cold steel with Rock wool |

|

Automatic temperature controller |

4 sets ; Range: 0°~160° |

|

Infrared heating tube |

30pcs ; Power: 30kw |

|

Conveying device |

Chain reciprocating |

|

Air cooling device |

1 set ; Power: 200w |

|

NO. 4 Auto face glue spraying section |

|

|

Appearance size |

3000*1000*2000mm |

|

Framework |

Steel welding |

|

Damp proof lamp |

1 pc ; Power:100w |

|

Automatic pressure spray tank |

1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

|

Conveying device |

Chain reciprocating |

|

Automatic spray gun |

4 sets (spare parts) |

|

Manual patch glue gun |

4 sets |

|

Dust control of axial flow fan |

1 set ; Power: 200w |

|

Automatic glue machine motor |

Servo motor ; Power: 750w |

|

NO. 5 The second time drying section |

|

|

Appearance size |

30000*1000*1200mm |

|

Framework |

Steel welding |

|

Frame type thermal insulation wall |

1.2mm cold steel with Rock wool |

|

Automatic temperature controller |

4 sets ; Range: 0°~160° |

|

Infrared heating tube |

30pcs ; Power: 30kw |

|

Conveying device |

Chain reciprocating |

|

Air cooling device |

1 set ; Power: 200w |