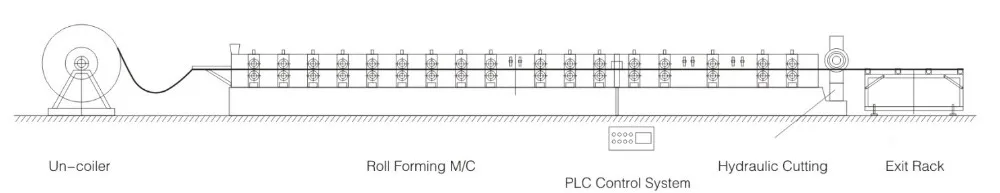

Processes and components

Processes: Man-made uncoiler—Roll forming machine—PLC system-Hydraulic system-Blade—Receiving table

Flow chart:

Main technology:

|

1. |

Raw Materil |

PPGI,PPGL, GI,GL |

|

2. |

Thickness |

0.3-0.8mm |

|

3. |

Uncoiler |

5 Tons Manual Uncoiler |

|

4. |

Roller Station |

11 Steps |

|

5. |

Shaft Material |

70mm And No.45 Steel |

|

6. |

Roller Material |

No.45 Steel |

|

7. |

Transport |

Chain Transport |

|

8. |

Forming Speed |

8-12m/min |

|

9. |

Motor Power |

3KW |

|

10. |

Voltage |

380V 50HZ 3Phase |

|

11. |

Cutting System |

Hydraulic Cutting |

|

12. |

Control System |

Detal PLC |

ptional Choice

|

1. |

Electric Uncoiler/Hydraulic Uncoiler |

|

2. |

Robstic Structure |

|

3. |

Automatic Stacker |

|

4. |

Logo Punching Machine |

|

5. |

Safety Cover |

Main Components

|

No. |

Name |

Unit |

Qty |

|

1 |

Manual decoiler |

set |

1 |

|

2 |

Main forming machine |

set |

1 |

|

3 |

PLC control system |

set |

1 |

|

4 |

Hydraulic pump station |

set |

1 |

|

5 |

Post cut |

set |

1 |

|

6 |

Electric motor |

set |

1 |

|

7 |

Output table |

set |

1 |

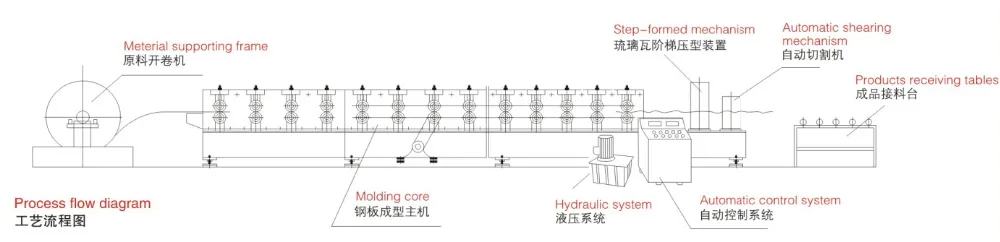

Processing flow diagram of machine